Product specification

Online tobacco moisture measurement using microwaves

Description

MOCON-TAB is an online measuring system for determining the moisture in tobacco using ultra-low frequency microwaves (925-980 MHz).

The average moisture content of the entire cigarette pack and the moisture content per unit section of the cigarette pack are determined.

The contactless measurement has no influence on the production process.

Per second high test accuracy and repeatability of up to 0.1%, can be 8 data recorded and displayed as a bar graph in a trend diagram.

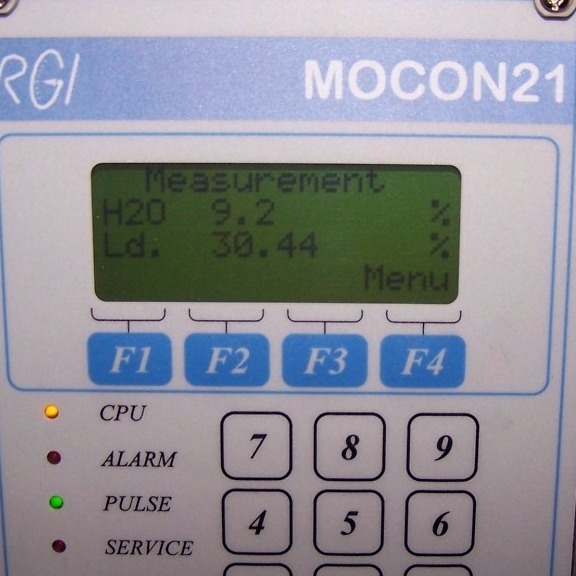

MOCON 21

Evaluation unit for microwave moisture measurement

more ... >>>

RGI 8403 / 8406

Microwave moisture measuring modules

more ... >>>

MOISTERM

PC software service / diagnostic tool

more ... >>>

Details

Software calibration and operation are simple and convenient.

The software can immediately display the moisture data in real time and display the internal moisture of the cigarette pack.

8 different tobacco qualities can be saved and 8 linear storage channels can be supported.

The measuring system offers you multi-port output, 4-20 mA, RS232 and other options for data exchange with PLC or DCS systems.

Quality control can be provided with real-time moisture data remotely to adjust the process in time and meet the required quality requirements.

Moisture measuring range:

● generally 0-60% (depending on the application)

● waste paper 0-30%, wood chips 40-55%

● strongly dependent on the product for cigarette packs and cotton

● Resolution: 0.01%

Average absolute measurement error:

● waste paper 1%

● Wood chips 2%