Product specification

Continuous determination of ash in coal

Description

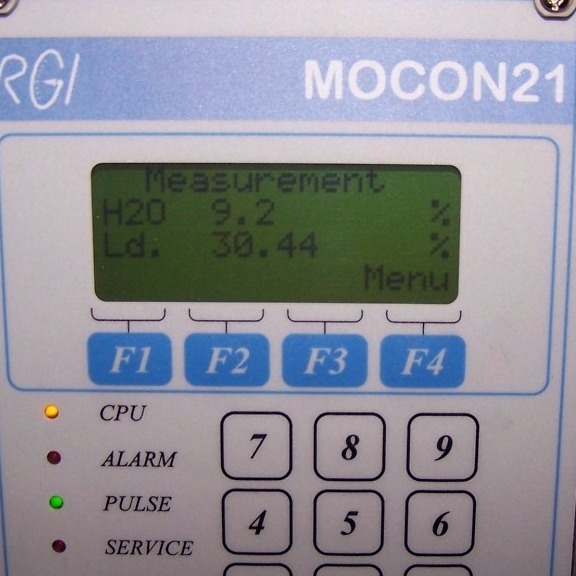

Complete measuring system for determining and calculating the ash content in coal consisting of two measuring lines, each with a radiation source, the associated detector and an industrial PC with the software ASH-MONITOR

ASH-MONITOR

PC-Software

more ... >>>

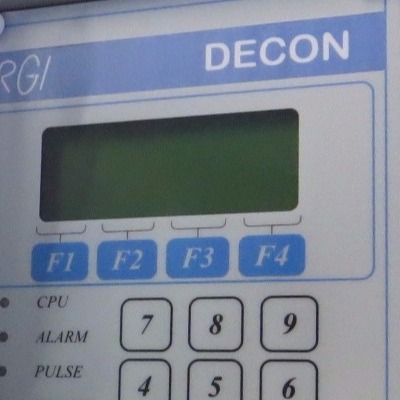

ABSxx

Screening container with radiation source

more ... >>>

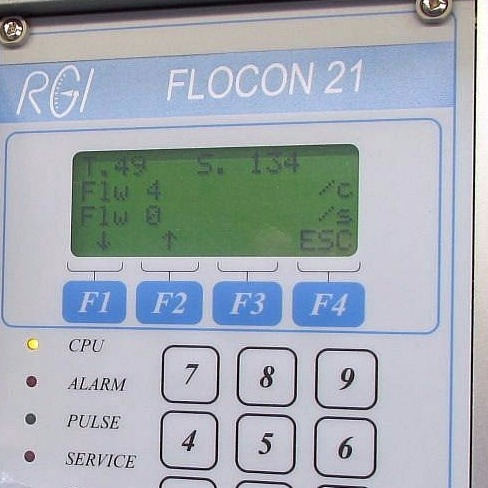

ADxx

Radiation detector

more ... >>>

Measuring principle

Electromagnetic waves such as X-rays or gamma rays are absorbed in the material in different ways, which is why it depends on the energy of the radiation and on the material itself, how it is absorbed.

High energy waves and low atomic numbers are absorbed depending on the density (or bulk density) of the material.

In addition, the absorption is of course also dependent on the layer thickness.

This means that the absorption depends on the weight of the material through which the radiation has passed (the weight increases as the path becomes longer or as the density increases).

Density and thickness can be measured using radiation: if one value is constant, the other can be calculated.