Product specification

Radiometric belt weigher for continuous load measurement

Description

A continuously measuring balance is expected to determine the amount of a flow and to deliver the delivered amount per time interval or the integrated amount over a period of time as an output value.

For this task, this means determining the weight of the flow rate for a section:

● gravimetric - section must be movably supported, since weight can only be determined via a deflection

● radiometric - weight is not determined directly via gravity, but by means of radiation of the mass.

ASBxx

Screening container with radiation source

more ... >>>

DDxx

Szintillator detector

more ... >>>

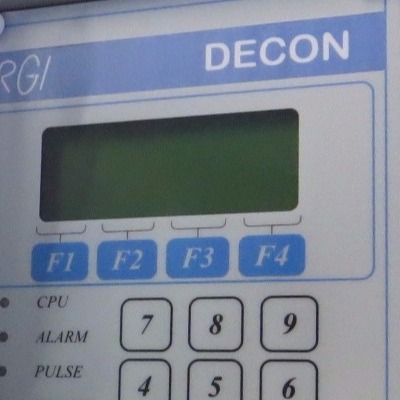

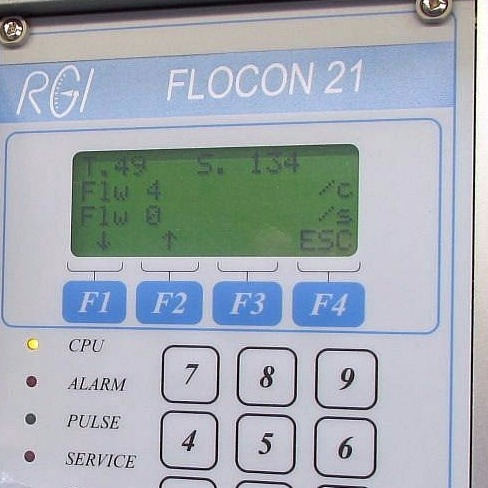

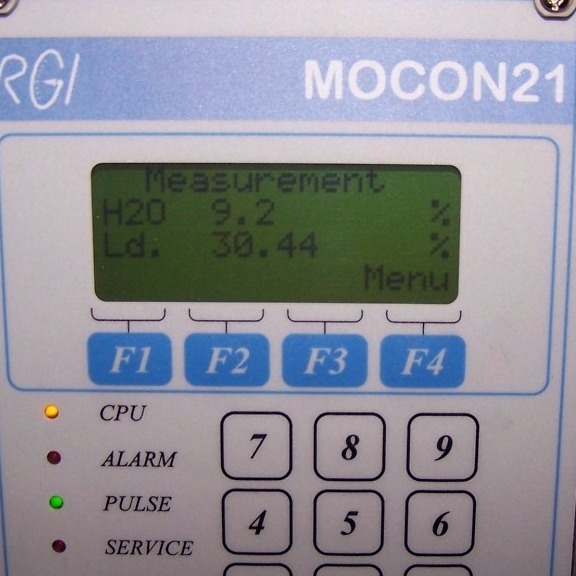

MACON21

Controller for radiometrc belt weigher

more ... >>>

Functionality

If x-rays can show a bone in one leg, it is because the bone has a higher density than the adjacent tissue.

If there are enough gray tones, the film shows an exact image of the density distribution in the leg: with a thicker leg, the intensity of the radiation coming through is also lower than with a thin leg.

When "screening" the occupancy of a conveyor belt, the density distribution is also measured and the mass is determined therefrom.

Decisive for the weakening of the radiation is the bulk density and the path that the radiation travels in the required material, i.e. the level of coverage.

The result is the mass per unit area.

Since the bandwidth is known, this value only has to be multiplied by the speed of the flow rate in order to arrive at the weight per unit of time.