Product specification

Measuring system for potash content determination using shaft calimetry

Description

The measuring system monitors and logs two measuring locations (containers).

At each measuring point, four gamma radiation detectors are attached to the surface of the container.

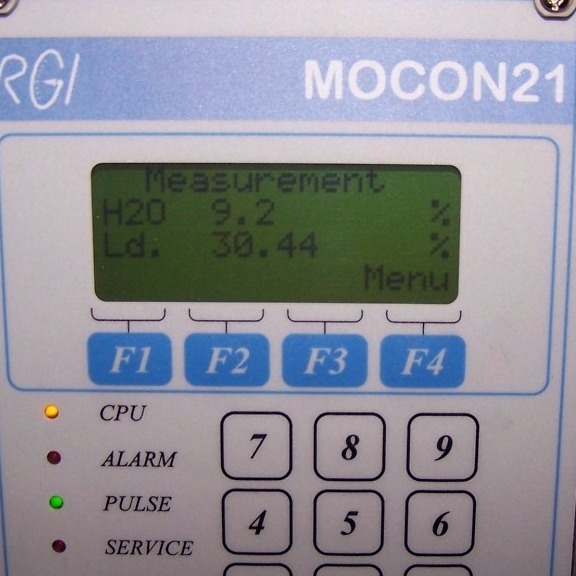

A surface measurement for determining the K40 content is carried out by means of the detectors for ionizing radiation and the K40 delivery quantity is determined with the aid of the weight information provided to the system.

The measuring system usually consists of the detectors, an industrial PC and the software installed on them.

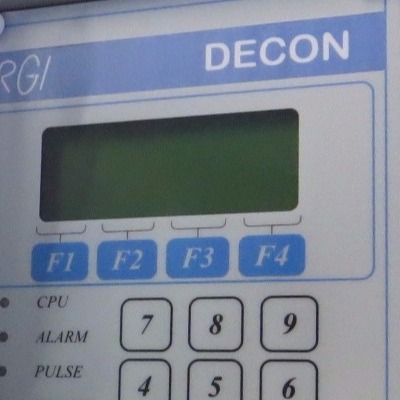

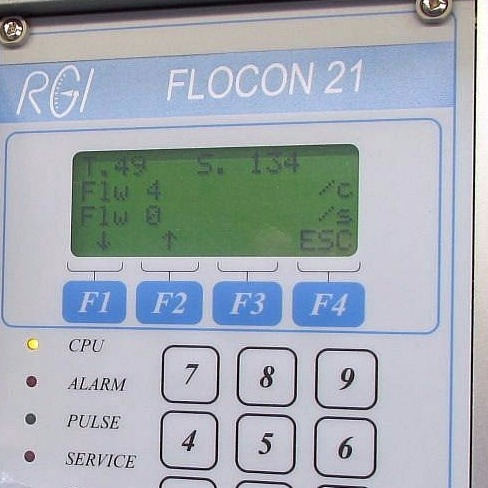

PDxx

Detectors for potassium content determination

more ... >>>

SVW

Software for potassium content determination

more ... >>>

Measuring principle

An artifical radioactive source - encapsulated in a radiation protection container -, which emits bundled γ-rays, is usually used for radiometric measurement.

These γ-rays are dampened when penetrating the product to be measured and received by an opposite detector.

The measured radiation intensity is proportional to the density or the mass flow.

Appropriate calculations by an evaluation unit approximately determine a proportional weight value from this change.

When weighing potash normally can be used the material's natural radiation.

Advantages of this procedure:

● independent of process pressures, temperatures and all chemical properties of the medium.

● relatively accurate

● sometimes the only solution in very unfavorable cases.

Disadvantage:

● high price,

● complex adjustment procedure