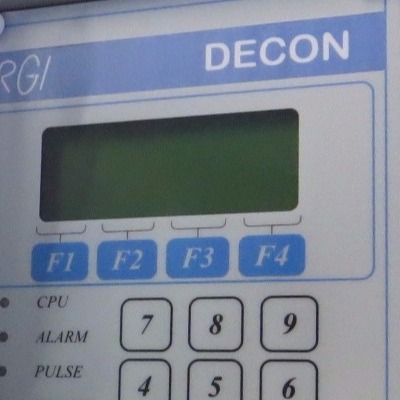

Product specification

Evaluation unit for non-contact density measurement

Description

The heart of the DECON 21 is a microprocessor-controlled small computer for calculating the density or concentration or solids content of liquids, suspensions and bulk materials directly on pipes or container walls, which in combination with a radiation source and a detector forms a complete measuring section.

By determining the absorption of radioactive radiation as it passes through a substance, its density and various measurement variables derived from it, such as solids content, acid strength or concentration, can be measured without contact.

Since the radiometric density measurement is independent of the physical state of the substance (solid / liquid, hot / cold, etc.), it can be used successfully with almost all bulk goods, liquids and solutions / dispersions / emulsions.

Because the radiation can also penetrate steel walls, measurements can be carried out directly on pipes and containers.

The measuring section consists of a radioactive source, the radiation of which emerges from a shielding container as a thin measuring beam, a scintillation detector DDxx, which registers the attenuated radiation after crossing the substance to be measured, and the evaluation unit DECON 21, which processes this information.

ABSxx

Container for radiation source

more ... >>>

DDxx

Radiation detector

more ... >>>

Technical data

Power supply:

● Standard: - 230V-

● Optional: - 115V-, 24V-, 24V =

Counter inputs:

● 2 galvanically decoupled 16 bit counters

● Dead time # 1.5μs

● Maximum count rate 500 kHz (with 8 measurements / s)

● 1, 2, 4 or 8 measurements per second

Digital inputs:

● 4 electrically isolated inputs (switching threshold $ 5V)

● maximum input voltage 24V

● individually switchable logic

Digital outputs:

● 3 potential-free relay contacts (changeover contacts)

● max. 110V DC, 125V AC, 1A; Max. 30W

Current output:

● Standard: 1 analog output (galvanically isolated)

● 0..20mA or 4..20mA adjustable

● Accuracy # 0.5% / freely scalable

● Detection of line breaks in both operating modes

● Optional: 2nd current output (magnifying glass function)

Miscellaneous:

● Illuminated 4-line LCD display (4x16 characters)

● Keypad with tactile and acoustic feedback

● Signal generator

● Battery backup via lithium cell

● Integrated watch dog function

● optional: serial interface

Temperature range:

● 0 ° -55 ° C (ambient temperature)

Dimensions:

● WxHxD 101.4mm (20HP) x 128.2 (3U) x 188mm

Weight:

● 518g (without case)

● 5100g (with wall housing)

Wall housing:

● IP 54 classification