Product specification

PC service tool for moisture determination

Description

MoistTerm is a service-oriented software tool from RGI that helps with setting up, parameterizing and checking the microwave moisture sensor 7406.

This software works with the humidity sensor firmware 7406 of the transmitter and receiver and enables easy setting of all measurement parameters depending on the application.

As soon as the parameters of the moisture sensor 7406 are set, it can be separated from MoistTerm.

All parameters are stored in the microcontroller of the 7406 humidity sensor and are retained in its EEPROM in the event of a power failure.

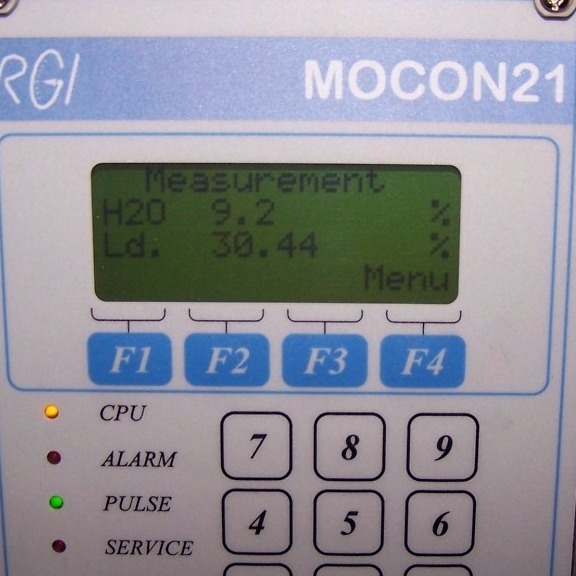

For routine use, the evaluation unit for the 7406 humidity sensor is sometimes connected to the pulse frequency output of the MOCON 21.

All operating functions and the technical description are in the supplied MOCON 21 manual.

For other applications, the 7406 humidity sensor is connected to the RS485 bus system, which connects further RGI modules to an industrial PC that functions as the central measurement data acquisition and evaluation station

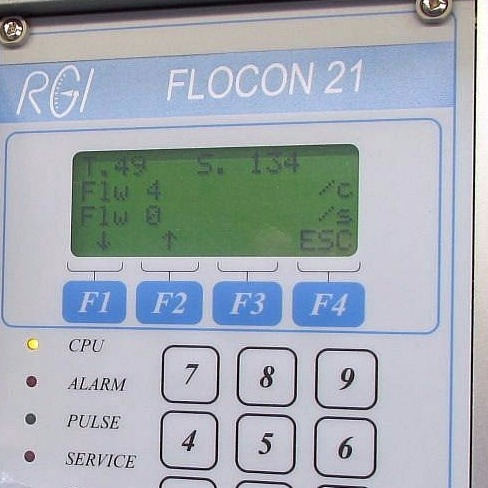

MOCON 21

Controller for moisture measurement on conveyor belts

more ... >>>

Details

The 2.4 GHz ISM band-based microwave moisture sensor 7406 consists of 2 modules with built-in front-end electronics: a receiver and a transmitter unit, each with an HF antenna, which measures the moisture of almost electrically non-conductive bulk material in industrial applications.

The material must be between these two components (e.g. on a conveyor belt).

Transmitter 7406 sends a constant pattern of pre-programmed RF power on a fixed frequency channel, which starts approx. 10 seconds after the device is switched on after the built-in HF module has initialized.

The receiving unit 7406 receives the RF signal level at the pre-programmed frequency, which process starts approx. 10 seconds after switching on after the device has initialized the built-in RF module.

From now on, the 7406 unit repeatedly generates the values of the received signal strength indicator (RSSI signal = logarithmic value of the received RF signal) of its RF part.

The repetition interval (at least 0.25 seconds) and the receiver frequency are constant and pre-programmable and are customer-specific parameters.

All system parameters are stored in the non-volatile EPPROM of the corresponding modules.