Product specification

Radioactivity measurement system for trucks and trains

Description

Der Zweck der Anlage RMA54 ist es, vagabundierende radioaktive Quellen zu entdecken.

Aus physikalischen Gründen kommen nur Gamma-Strahlenquellen in Frage, da Beta- und Alphastrahlen z.B. von der Bordwand eines LKW abgeschirmt werden.

Je nach den Gegebenheiten, aber auch dem Detektorgehäuse wird es bereits schwierig, niederenergetische Gammaquellen, z.B. Am-241 zu detektieren. Grundsätzlich ist dies aber möglich.

Üblicherweise besteht die Messtrecke aus:

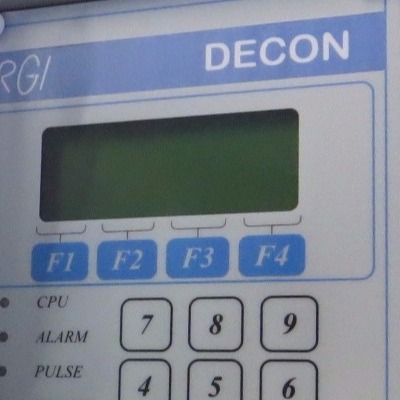

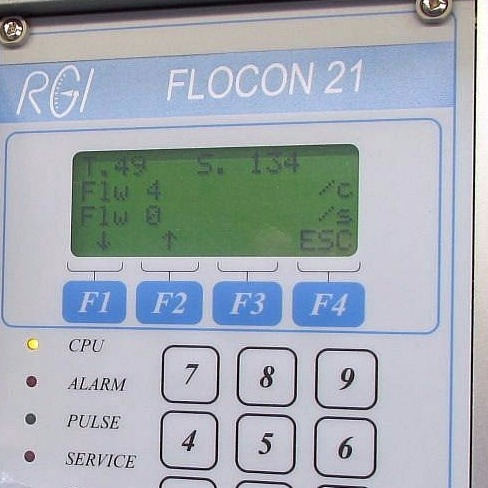

● RD54

Strahlendetektoren

siehe auch ...

● US-Sensoren als Lichtschranke (optional)

siehe auch ...

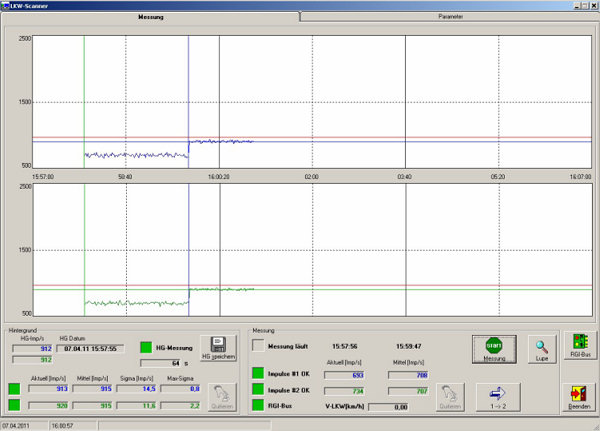

● Industrie-PC mit Auswertesoftware

siehe auch ...

Application

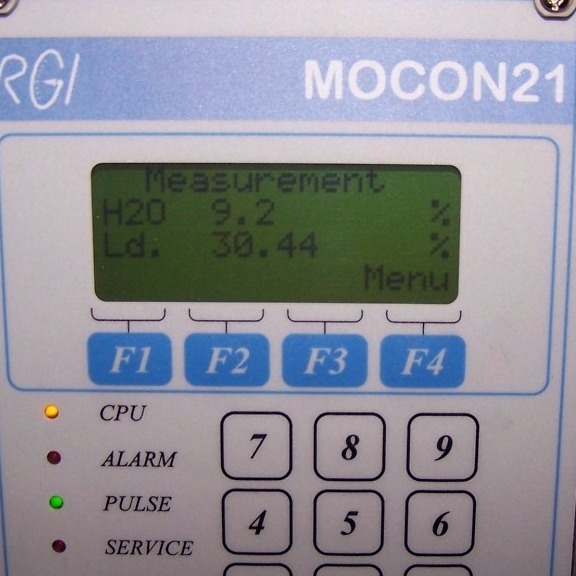

The RGI Portal Truck Radiation Monitoring System monitors the entire vehicle online and thus the entire amount of radioactive radiation in the container.

The detector we have developed is twice as sensitive to radiation substances as other products and can differentiate between different types of radiation sources.

This "Gateway Vehicle Radiation Monitoring System" is usually installed at the entrance to recycling facilities for scrap iron to determine whether the scrap iron loaded in the truck contains radioactive substances that are harmful to the human body.

These include e.g. Cobalt (Co-60), cesium (Cs-137) and rubidium (Am-241), which emit gamma rays, which in turn can be detected by the system.

If gamma radiation has been detected in the material supplied, then a portable radiation detector must be used to find out exactly where the radiating material is.