Product specification

Online moisture measurement with microwaves

Description

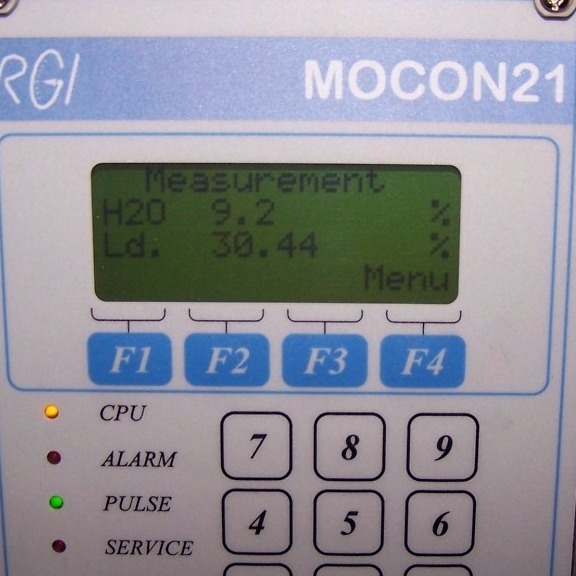

A complete measuring system for online moisture measurement, consisting of the microwave modules RGI 8403 and an industrial PC with the evaluation software FANAL W32.

In most cases, the occupancy on a conveyor belt varies, i.e. bulk density or height change, but the system provides moisture values without recognizing whether they are caused by changing moisture or quantity, which is why it is absolutely necessary to record this varying load during the moisture measurement in order to be able to clearly assign the measured value to the moisture .

The information about the assignment can e.g. from a belt scale as a 0...4-20 mA signal, but if the delivery rate is not of interest, only a point measurement of the occupancy can be carried out with an ultrasonic range finder.

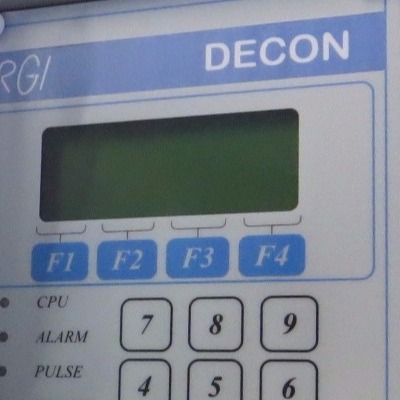

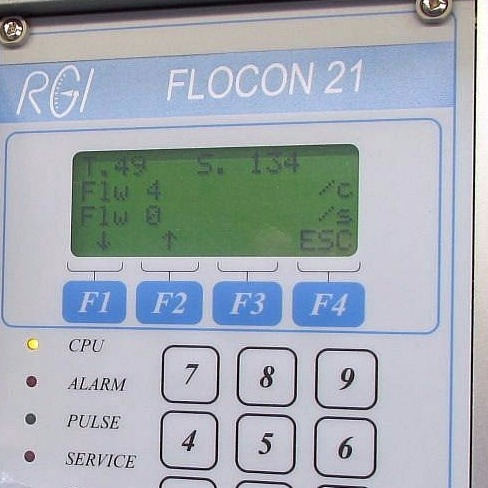

RGI 8403

Microwave modules

more ... >>>

FANAL W32

PC evaluation software

more ...>>>

Evaluation

Industrial computers from RGI

● based on a standard PC

● Connection to other systems (higher-level computers or PCS)

FANAL W32 software

● The menu is easy to understand despite the complicated physical and mathematical task

● Measured values in various forms:

- graphics

- different mean values

- and much more

● Display of all results on the color monitor

● Reading possible over a distance of several meters

● Data can be saved for up to 1 month

● Display in table format or as line graphics

● modern color monitor enables:

- easy calibration

- higher accuracy

- Checkability of various parameters for plausibility