Product specification

Truck waste paper / straw bale microwave moisture measurement

Description

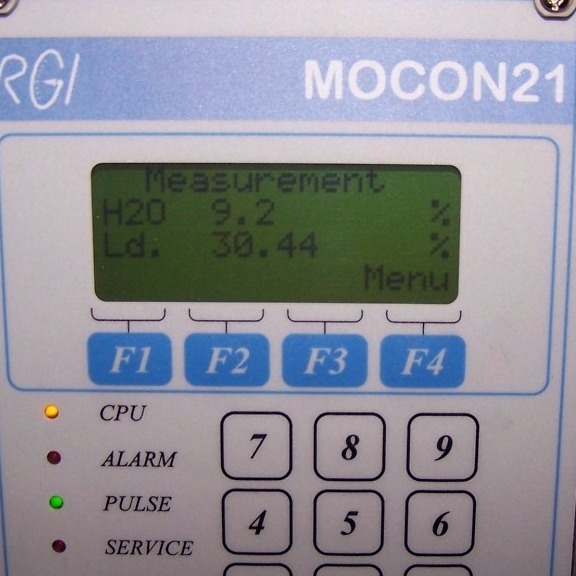

MOCON-LKW is an online measuring system for determining the moisture in the cargo (paper, straw) of trucks using ultra-low frequency microwaves (925-980 MHz).

The loaded truck drives through the RGI 8406 microwave transmitter and receiver modules located on the left and right of the system.

Since microwaves penetrate the process material completely, the moisture of the load can be determined.

The technology guarantees a high level of measurement accuracy and precision: the color and surface structure of the material, dust and water vapor do not affect the measurement results.

The raw data of the microwave sensor measuring section are processed by the evaluation computer; the measurement result is the percentage moisture in the measured material.

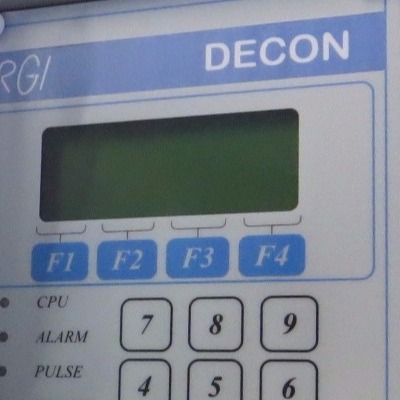

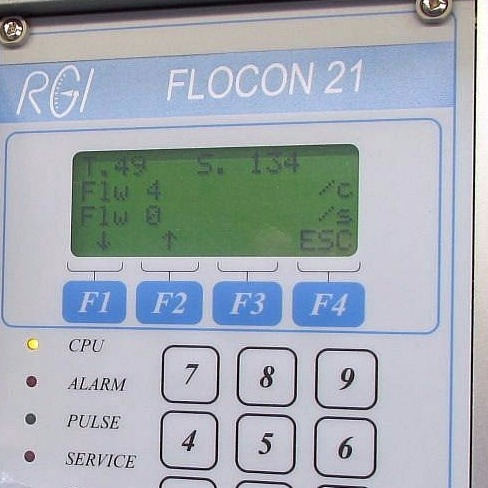

MOCON 21

Evaluation unit for microwave moisture measurement

more ... >>>

RGI 8403 / 8406

Microwave moisture measuring module

more ... >>>

MOISTERM

PC-software service-/diagnosis tool

more ... >>>

Details

High test accuracy: The repeatability for waste paper is 0.2 to 0.5% (automatic scan installation), for wood chips and straw 1%.

8 data can be measured per second, 128 data can be measured for the entire truck (depending on the speed),

It is easy and convenient to calibrate and operate the software.

Data will be immediately displayed simultaneously and in real time in a histogram and a trend diagram to reflect the moisture measurement.

30 different product qualities (e.g. paper of types 1 and 2, bark and corn stalks) can be saved with the software and 30 linear channel memories can be supported.

A multi-port output, 4-20 mA and Modbus RTU ensure data communication with ERP or PLC systems.

Moisture measuring range:

● generally 0-60% (depending on the application)

● waste paper 0-30%, wood chips 40-55%

● strongly dependent on the product for cigarette packs and cotton

● Resolution: 0.01%

Average absolute measurement error:

● waste paper 1%

● Wood chips 2%