Product specification

Potassium concentration measuring system

Description

The potassium concentration measuring system TWINKAM consists of an information processing and data display unit (industrial PC) and two scintillation detectors PD 125 connected to it.

The information processing unit TWINKAM itself consists of three parts and is integrated in a wall cabinet with a viewing window. The computing device is specially designed to calculate the content of potassium salts in a certain volume.

While the device is running, it is possible to interrupt the current measurement or to continue the interrupted measurement accordingly. It is also possible to set a specific measurement duration and thus the automatic completion of current measurements.

For details on the software functions, refer to the instruction manual of the measuring device and the instructions for calibrating the device.

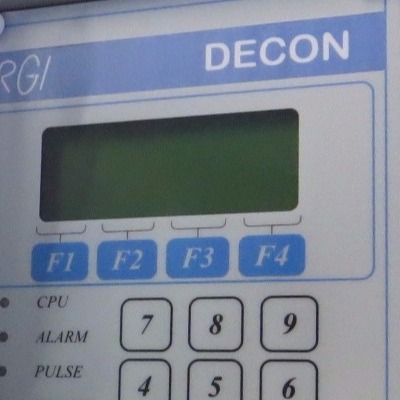

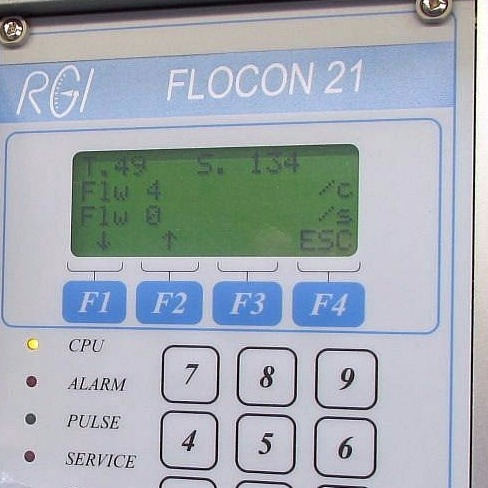

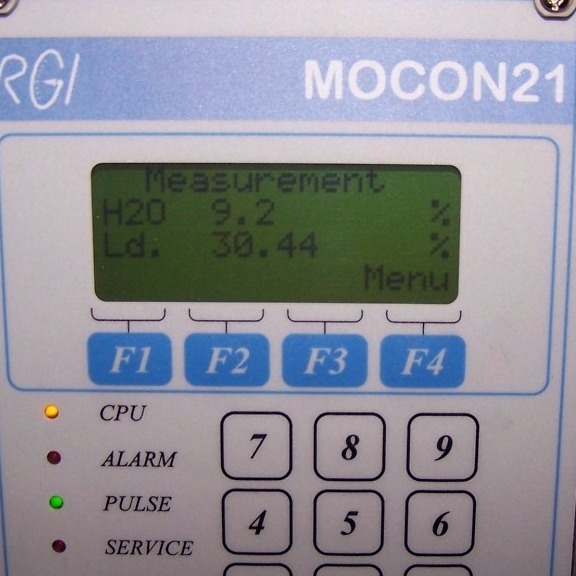

TWINKAM-RGI

PC-Software

more ... >>>

PD125

Szintillation detector

more ... >>>

PD 125

This RGI surface detector is an intensity detector for sensitive measurements in industrial environments.

Since a comparison of sensitivity, occupational safety and long-term potential detection methods speaks in favor of scintillation detectors, the PD 125 probe is designed with a scintillation detector that generates a photon avalanche when γ-radiation is absorbed, and is tuned by the system to the K-40 isotope.

The area detector is designed for use in aggressive industrial environments and is housed in a moisture-proof housing made of stainless steel (IP 67) for protection.

A cable is supplied for connection (standard length ~ 5 m). The lead housing with a window made of lead material in the lower area has a flange connection with the detector.

The detector for ionizing radiation itself is a NaJ / Tl crystal,.

An o ptically coupled secondary electronic multiplier converts it into electrical impulses. To do this, it requires an operating voltage of up to 1500 V, which is generated and stabilized in the detector.

The electrical impulses go through two modeling stages, which largely suppresses the noise generated by the photomultiplier.