Product specification

Evaluation unit for single-channel radiometric belt weigher

Description

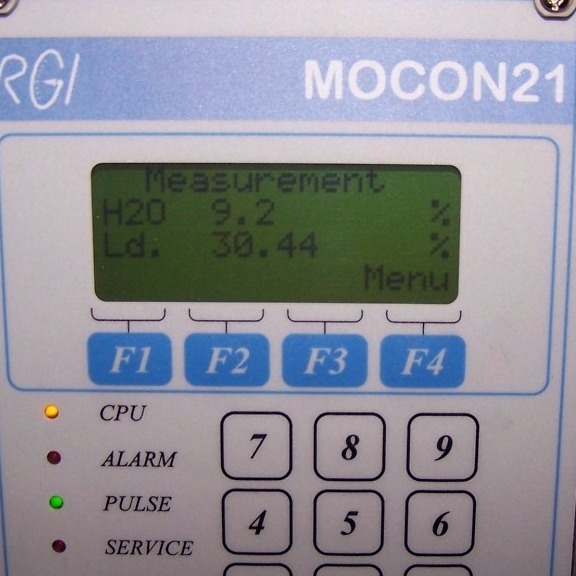

MACON 21 is a microprocessor-controlled controller for determining the conveying capacity of a belt or a belt conveyor in combination with a single-channel radiometric belt scale.

MACON 21 consists of a small computer that uses calibration coefficients from the beam attenuation and a belt speed signal to calculate the conveying capacity and outputs it as a current signal in the range 0 / 4-20 mA.

Optionally, the operation can also be carried out with an IPC / laptop that can be connected to another interface.

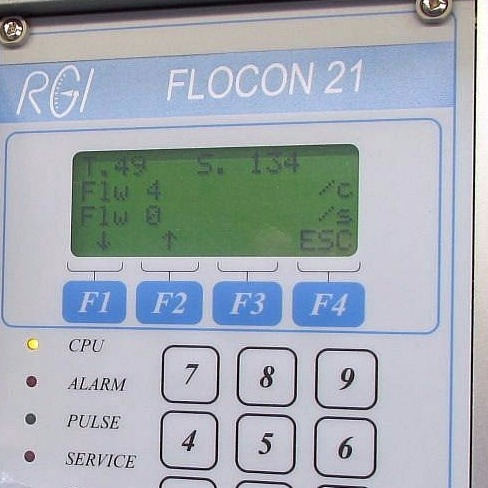

With the small computer control, all operational parameters are accessible via menu control in conjunction with a four-line LC display and can be quickly adapted to the respective measurement situation.

Thanks to the detector geometry of the radiometric measuring section, it is possible to reliably measure the delivery rate even when the occupancy profile changes.

The decrease in the activity of the radioactive emitter used is automatically compensated for in accordance with the half-life.

The system is calibrated using sample weighing with the conveyor belt running, using a mechanical belt weigher or a truck / track weigher.

All inputs and outputs are galvanically isolated from the computer and are protected against reverse polarity or interference (EMC) by a comprehensive protective circuit.

The measured value is output as an analog 0 / 4-20mA signal with 10-bit accuracy (better than 0.5% of the selected measuring range) and any scaling.

RMBW

Radiometric belt weigher

more ... >>>

Technical data

Power supply:

● Standard: 230 Vac

● Optional: 110Vac, 24 Vac, 24 Vdc

Counter inputs:

● 3 galvanically decoupled 16 bit counters

Dead time:

● <1.5 μs

Maximum count rate:

● 250 kHz (at 4 measurements / s)

● 1, 2 or 4 measurements per second

Digital inputs:

● 4 electrically isolated inputs:

- 5V switching threshold

- maximum input voltage 24V

- individually switchable logic

Digital outputs (optional):

● 4 potential-free relay contacts (changeover contacts)

- Max. 110V DC, 125V AC, 1A; Max. 30W

Current output:

● Standard:

- 1 analog output (galvanically isolated)

- 0… 20 mA or 4… 20 mA selectable

- accuracy better than 0.5%

- freely scalable

- Detection of line breaks in both

Operating modes (optional)

Miscellaneous:

● Illuminated 4-line LCD display (4x16 characters)

● Keypad with tactile and acoustic feedback

● Signal generator

● Battery backup via lithium cell

● Integrated watch dog function

● optional:

- 4 potential-free digital outputs

- 2nd current output

Temperature range:

● 0-55oC ambient temperature

Dimensions:

● WxHxD: 200x280x300 mm

Weight:

● approx. 5 kg

Wall housing:

● IP 65 classification