Product specification

Compact system for density measurement

Description

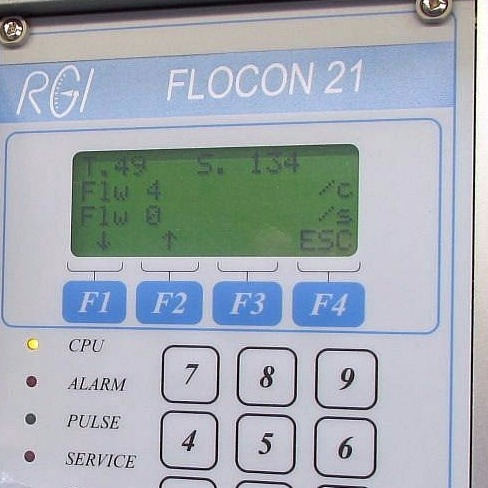

The compact density measuring system DD50_µC consists of

• modified DD 50 detector

• Compact housing with integrated CPU board (RGI-9014)

• ABSxx shielding container with appropriate source

• Industry PC

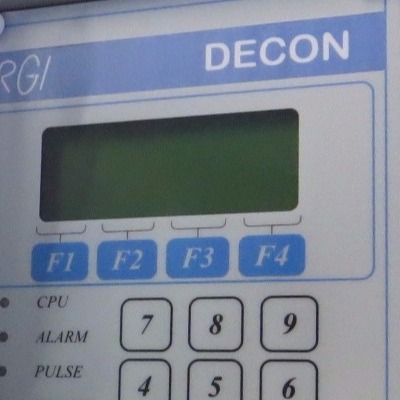

• PC evaluation software D-DECON

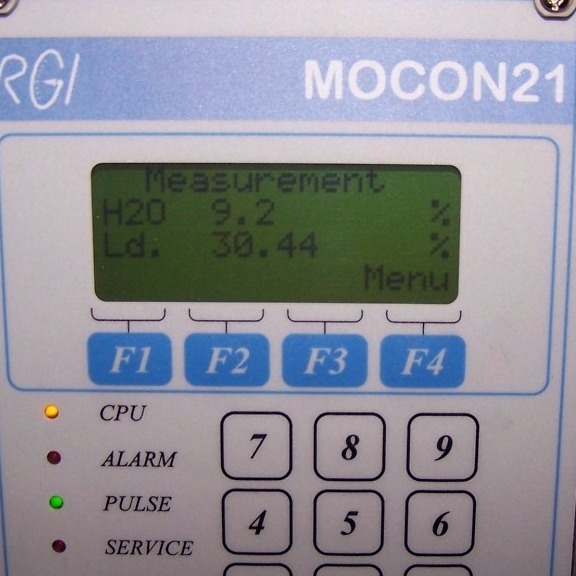

The system determines the density of this material from the weakening of ionizing radiation by a material flow.

In order for the system to work correctly, each detector must be calibrated and the system parameters set before start-up.

In normal operation, each detector outputs the density value averaged over a short period of time (default: 10 s).

DD 50

Density detector

more ... >>>

ABSxx

source container for radiometric measuring systems

more ... >>>

D-DECON

Software for density compact system DD50_µC

more ... >>>

Details

Following Comprehensive settings, displays and evaluations are possible using the clear and intuitive user interface of the D-DECON PC software:

Detector configuration

● address (0 ... 15)

● firmware (display ONLY)

● measuring frequency (1/2/4 s)

● current output (0-20mA or 4-20mA)

● measuring range (min. And max. In g / cm³ or kg / dm³)

● pulse window (expected min. And max. In cps)

● current scaling

● slope Ka, µ (default setting Ka = 1.4286)

● offset Kb (default setting Kb = 1)

● averaging time (1 ... 60 s, default setting = 10 s)

● calibration time (default = 5 min)

● pipe diameter (mm, default = 100)

● meter number (1, 2 or 3, default = 1)

● current output number (1 or 2, default = 1)

The software D-DECON runs as embedded software on industrial PCs under all versions of the Windows 2000 and Windows XP operating systems.

Using the D-DECON PC software, each detector can be individually configured and calibrated for commissioning.