Product specification

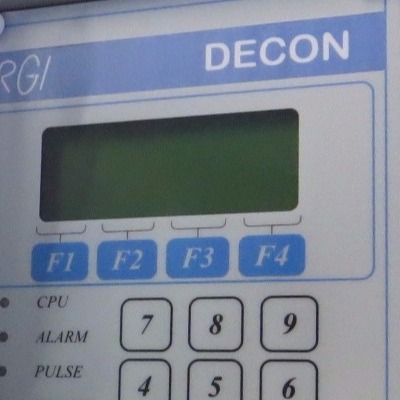

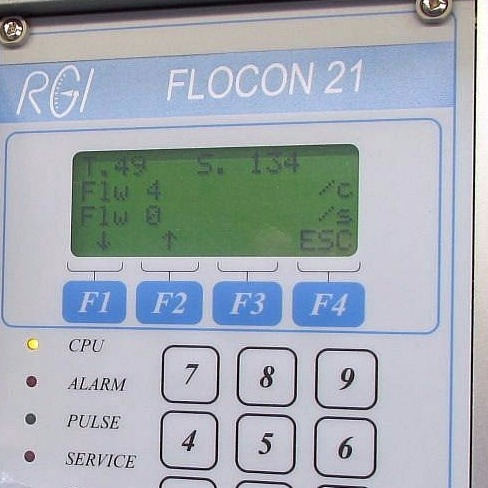

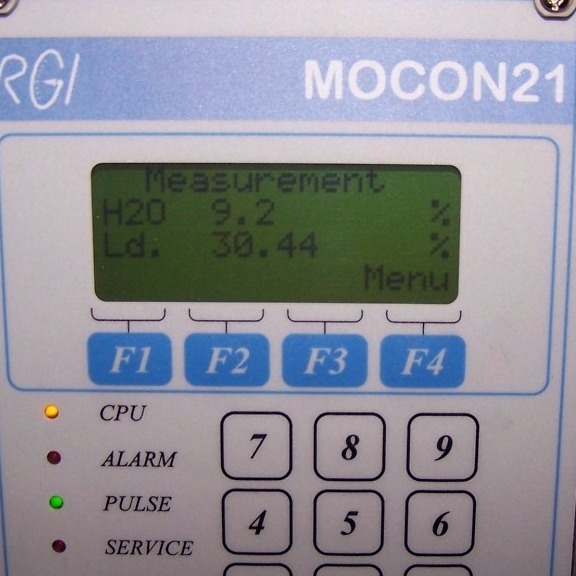

Evaluation unit for radiometric point level detection

Description

BARCON 21 is a processor-controlled evaluation unit for determining limit levels in closed containers, which forms in combination with a radiation source and a detector a complete measuring system.

ABS80

Shielding containers, containers for radiation sources

Stainless steel housing, shielding lead, source Cs₁₃₇

more ... >>>

LD25

Radiation detector

Scintillator: NaJ / TI (normal 25x25mm)

more ... >>>

Technical data

Power supply:

● Standard: - 230V

● Optional: - 115V-, 24V-, 24V =

Counting input:

● 2 counters (1, 2, 4 or 8 measurements / s)

Digital outputs:

● Standard:

1 potential-free relay contact alarm

1 potential-free relay contact watch dog

Temperature:

● 0 ° -55 ° C (ambient)

Dimensions:

● WxHxD: 50.5 mm (10HP) x 132.5 (3HU) x 160mm

Weight:

● 318g (without case)

Casing:

● IP 54 (28 HP) die-cast aluminum