Product specification

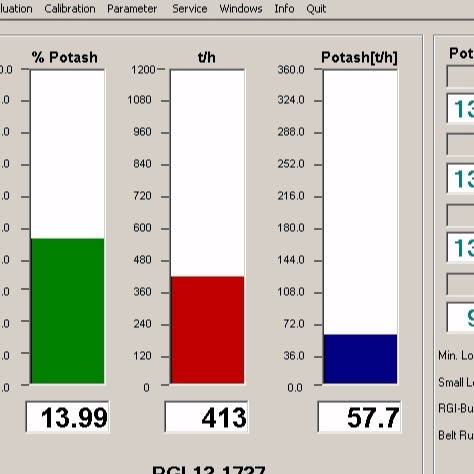

Software for Radiometric Potash Belt Scale

Description

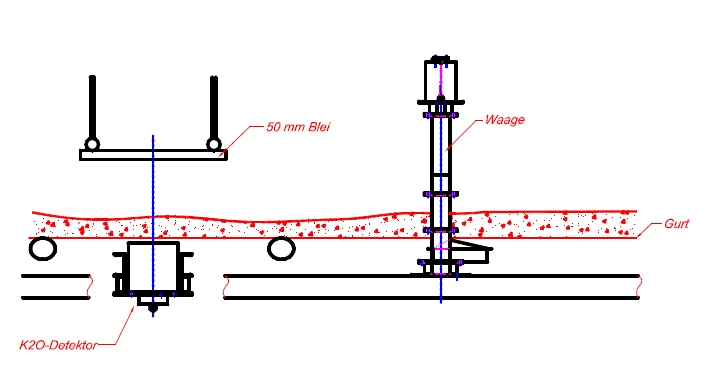

The radiometric potash belt scale from RGI is used for uninterrupted, continuous measurement of the mass of a material to be transported on the conveyor belt and the determination of its potassium mass fraction.

The identical RGI detectors of type WDxx or MDxx are used for the mass determination.

The number of detectors to be used depends on the relevant general conditions, such as the width of the conveyor belt, and is usually between five and eight.

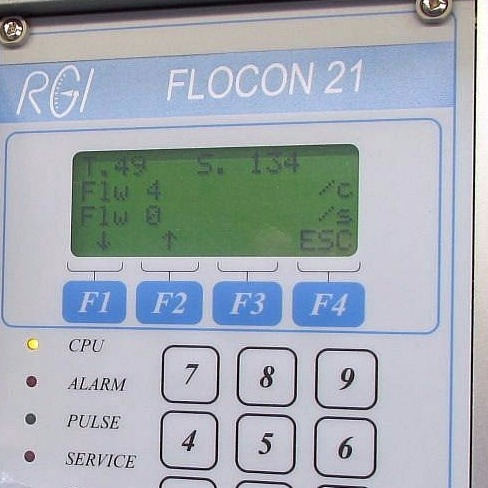

To determine the mass, the transport speed of the measured material on the conveyor belt is necessary. This information can be supplied by a tachometer in the RGI measurement system package or by an external information system.

ASBxx

Container for radioacive source

more ... >>>

MDxx, WDxx

Detectors for mass measuring systems

more ... >>>

Details

This software is used for commissioning, parameterization, data acquisition and processing for a potash route.

With its help can be carried out extensive settings, displays and evaluations:

● Numbering the counters in the program

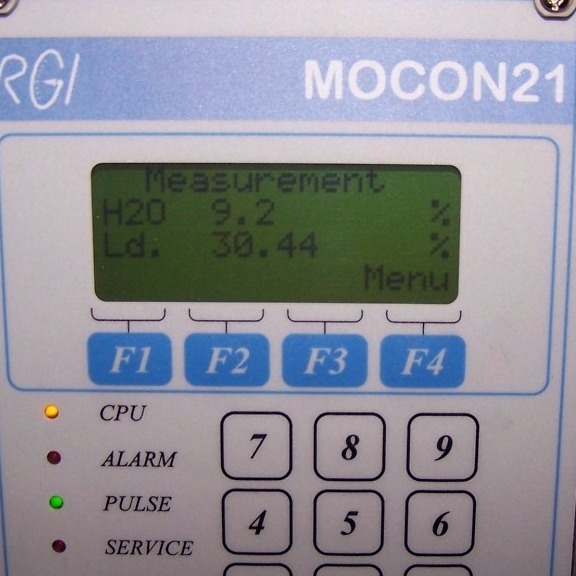

● Check the measurement

● System parameters

● Mass parameters

● Parameters of the potassium measurement

● Measurement of the zero level

● Measurement of the samples

● Management of the measured samples

● Determination of the coefficients for evaluation

● Graphical display of samples

● Graphic corrections

● and much more