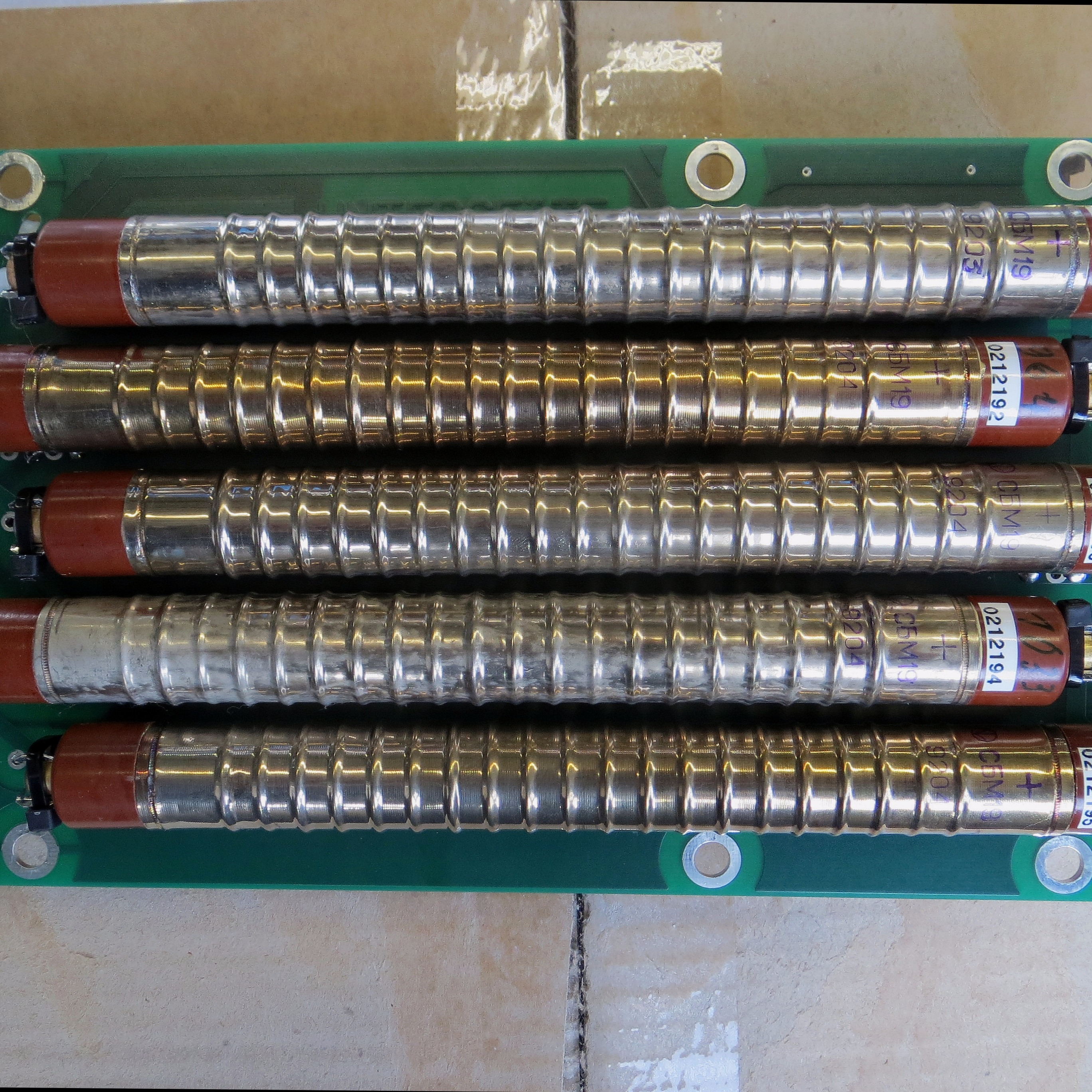

Another way is to use a plastic scintillation material, which is not as cheap as a counter tube, but is more sensitive and robust, which is why devices with plastic scintillation counters are used for the ß measurement in laboratory analyzers and for continuous measurements on filters.

However, applications for γ measurement cannot be counted, which is why they can be found on or in funnels, or brine containers or wherever there is enough salt.

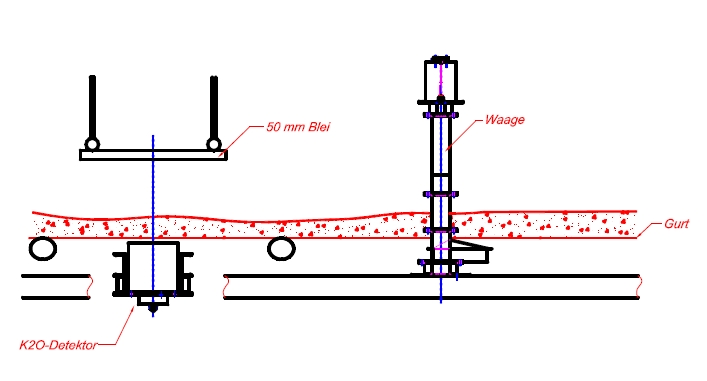

A special application is the measurement of γ radiation on a tape, the material of which is not sufficient to achieve the saturation layer thickness.

The simple measurement of the K-40 radiation is influenced by the variation of the bulk density and the layer, which is why the load must also be measured - either with a radiometric or an electromechanical belt scale so that the weight determined in this way can be used to correct the error to correct the changing loading of the conveyor belt.