The radiation in the crystal generates flashes of light, which are captured with a photomultiplier, converted into electrical impulses and then recorded by evaluation electronics and converted into a corresponding value.

For this purpose, this evaluation unit not only has to accomplish a high computing effort, but also take over the automatic correction of all changes due to temperature or possible aging of the electronic components, since the spectrum of the radiation must be analyzed and kept constant.

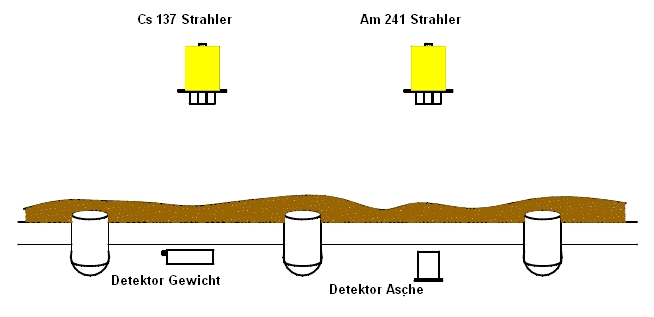

The radiation sources for the high and low energy are built into lead housings that only release the radiation in the direction of the detectors, whereby either the radiation source or the detector is installed below, the other part above the belt and thus the material to be measured.

Radiation source and detector together form a measuring section, whereby two measuring sections, which should have a distance of at least 2m from each other, are necessary in order to provide a usable, usable measurement result by the evaluation computer delaying the first signal and calculating it at the same time as the second.

In principle, it would be possible to build both radiation sources and both detectors in one housing each, but the separation of the two energies is more complex than two detectors and two lead shields, furthermore the mutual influences cannot be separated and experience has shown that the system is more difficult to control.

The detector and the radiation source must be mounted on a stable frame so that no changes in the distance distort the measurement.